Students Tackle Manufacturing Challenges in Summer Course

Hands-on course at Mississippi manufacturer offers CME students real-world experience, skills

GREENWOOD, Miss. - Students from the University of Mississippi's Haley Barbour Center for Manufacturing Excellence recently put their problem-solving skills to the test during a four-day value stream mapping course at Viking Range LLC in Greenwood.

The course is designed to give students hands-on experience with techniques used by businesses and industries to create efficient plant layouts, eliminate activities that add no value and reduce waste. After completing the course, students can:

- Effectively analyze a business or manufacturing process and create a value stream map

- Create a process and plant layout that minimizes non-value-added steps

- Develop visual management systems for business or manufacturing processes

- Formulate process and workplace improvements.

Sean Hildreth, a rising junior in mechanical engineering from Olive Branch, spent time at the production facility in May. His job was to manage the middle section of the oven assembly line, finding ways to eliminate unnecessary effort from the workers' processes.

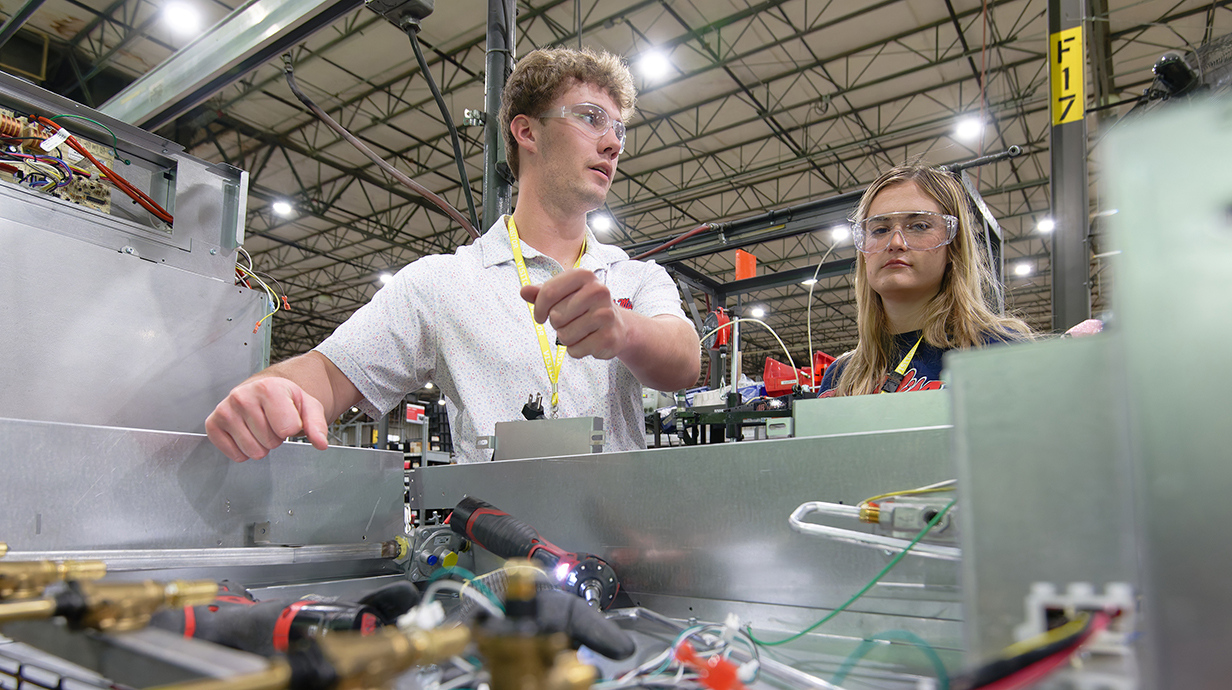

Kenneth 'Sean' Hildreth (left), of Olive Branch; William 'Mack' McEwan Fountain, of Oxford; and Roland Dear, of Jackson, go over ways to improve efficiency on the range assembly line at Viking Range in Greenwood. Photo by Hunt Mercier/Ole Miss Digital Imaging Services

"Working on a real-world project with Viking Range allowed me to take what I've learned in the classroom and apply it in a live work environment, transforming textbook concepts into something real," said Hildreth, who is enrolled in the center's manufacturing emphasis.

"This kind of engaging, hands-on learning sets CME students apart and gives us an edge when pursuing internships and starting our careers."

Using value stream mapping as a "blueprint" for processes, students gathered critical data such as process times, delays, inventory levels, staffing needs and information flow. The hands-on approach helped students understand the balance between value-added and non-value-added activities.

Beth Tackett, Viking's vice president of human resources, praised the professionalism and insights offered by the student teams.

"Every student presented with confidence and clear communication," Tackett said. "Teams delivered critical feedback with professionalism and tact. They developed solutions that were thoughtful, impactful and appear to have a high probability of success.

"The consistent and effective application of lean tools further demonstrated the students' depth of understanding."

The program's goal is to help participating manufacturers reduce waste, lower costs and improve speed and visibility in its operations.

The course also helps fill a critical need for engineers and other professionals who understand the manufacturing process, said Scott Kilpatrick, the Ole Miss center's executive director.

"These opportunities allow CME students to apply their lean manufacturing skills to real-world challenges while gaining firsthand exposure to the wide range of career paths available in manufacturing right here in Mississippi, from the Gulf Coast to north Mississippi and everywhere in between," Kilpatrick said.

"These companies truly are educational partners and play a vital role in helping the CME team accomplish our mission of creating the premier manufacturing talent pipeline for Mississippi and beyond."

Top: Ole Miss students (from left) Michael Hancock, of Houston, Texas; Sophia Johnson, of Winter Park, Florida; Vance Singer, of Biloxi; and Kenneth 'Sean' Hildreth, of Olive Branch, walk through the Viking Range manufacturing facility in Greenwood. The students, all enrolled in the Haley Barbour Center for Manufacturing Excellence, helped eliminate unnecessary steps and reduce waste at the plant as part of a four-day value stream mapping course this summer. Photo by Hunt Mercier/Ole Miss Digital Imaging Services

By

Jordan Karnbach

Campus

Office, Department or Center

Published

June 29, 2025