Facilities & Equipment

CME’s state-of-the-art facilities give students space to design, build, and test ideas with the same tools and technology used in today’s manufacturing industry.

Our facilities don’t just support learning — they drive it.

Every space inside the Center for Manufacturing Excellence (CME) is designed with purpose: to mirror real-world manufacturing environments and to prepare students for them.

From high-tech equipment to creative maker spaces and professional collaboration zones, CME offers more than access, it offers immersion.

Immersive, Industry-Ready Spaces

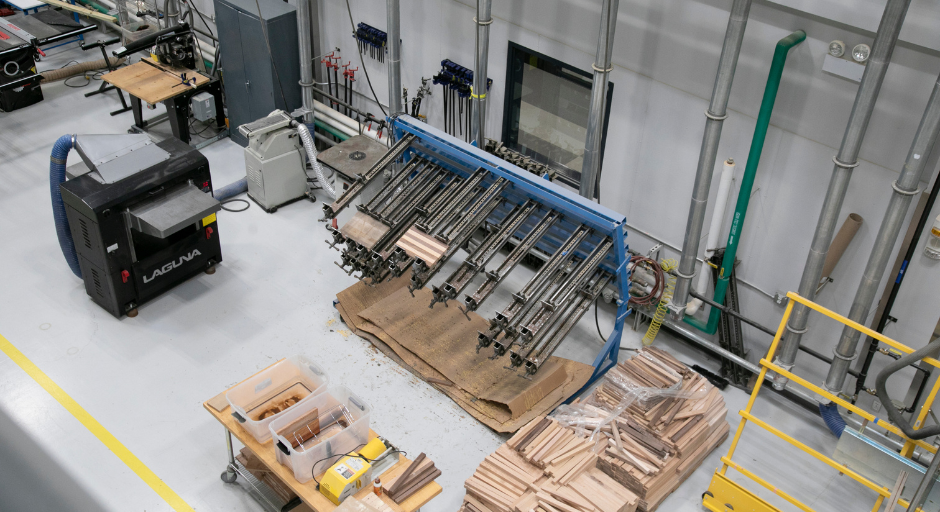

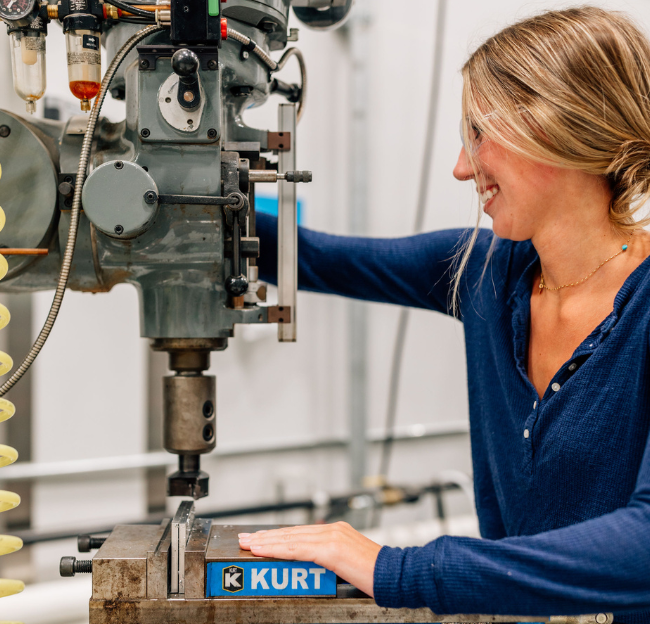

James G. Vaughan Factory Floor

The James G. Vaughan Factory Floor is a 12,000‑square‑foot, fully equipped space designed to replicate the environment of a modern manufacturing facility. Students gain hands-on experience in safety, workflow, and production using more than 70 industrial-grade machines and tools that include water jet cutting technology, CNC mills, welding stations, commercial 3D printers, manual metal working machines, wire EDM machines, paint booth, powder coating booth and more.

Capt. Max R. Miller Maker Space

The Capt. Max R. Miller Maker Space is where innovation meets experimentation. Furnished with 3D printers, laser engravers, 3D scanners, and an assortment of Milwaukee tools, it offers students a flexible, tech-rich environment to prototype ideas and deepen their manufacturing know-how beyond the factory floor.