The Hands-on Course in Tablet Technology

is a postgraduate educational program offered by the Pii Center for Pharmaceutical Technology. It provides an extensive review of conventional and advanced manufacturing technologies, including hot-melt extrusion, used to develop a variety of novel delivery and continuous manufacturing systems. The course, initiated in 1998, has trained over 2,000 attendees.

Interested in hearing about upcoming courses?

Learn More about the 2026 Tablet Course

The Hands-on Course in Tablet Technology, a post-graduate educational program offered by the Pii Center for Pharmaceutical Technology at the University of Mississippi School of Pharmacy, provides an extensive overview of conventional and advanced manufacturing technologies, including hot-melt extrusion, that is used to develop a variety of novel dosage forms.

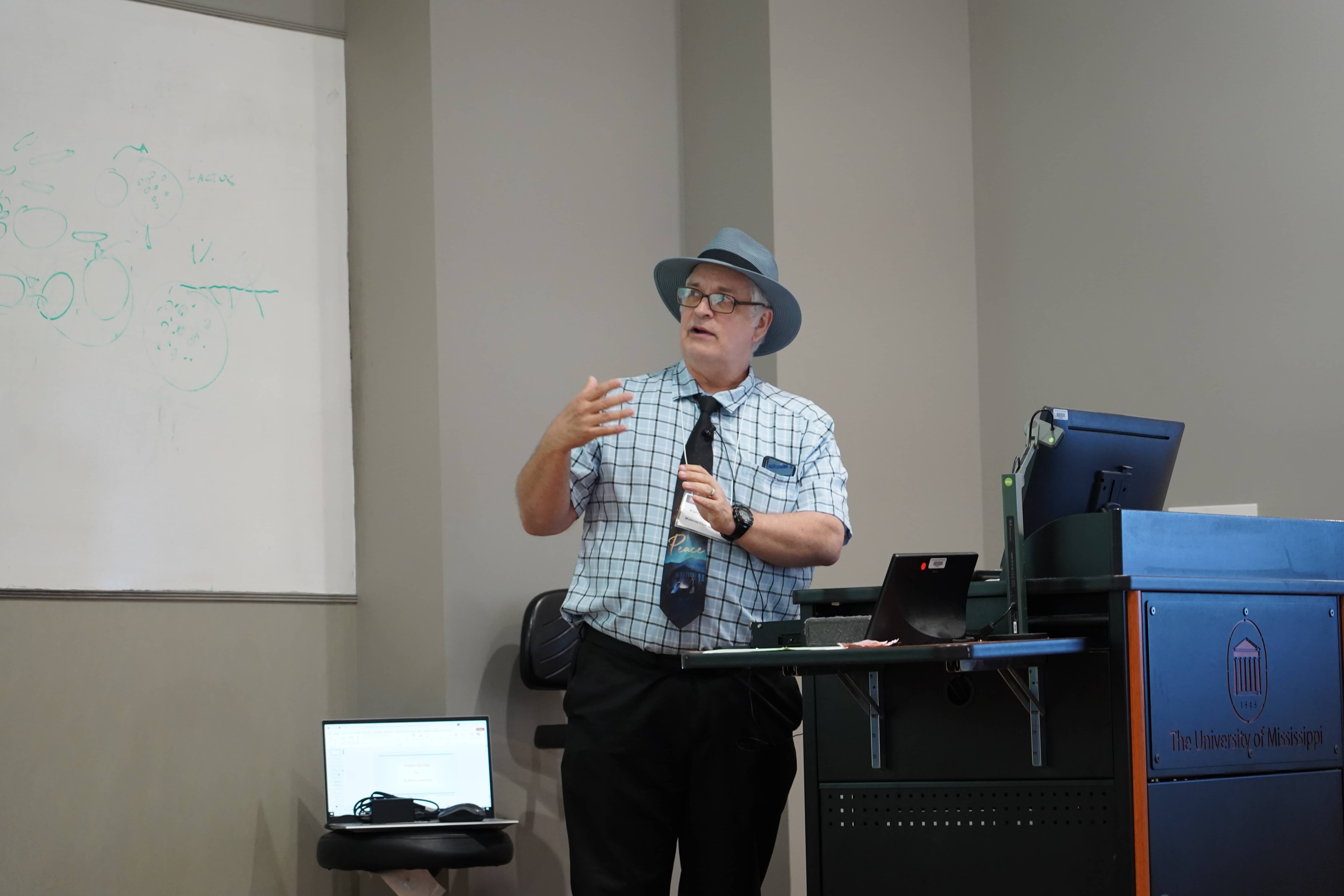

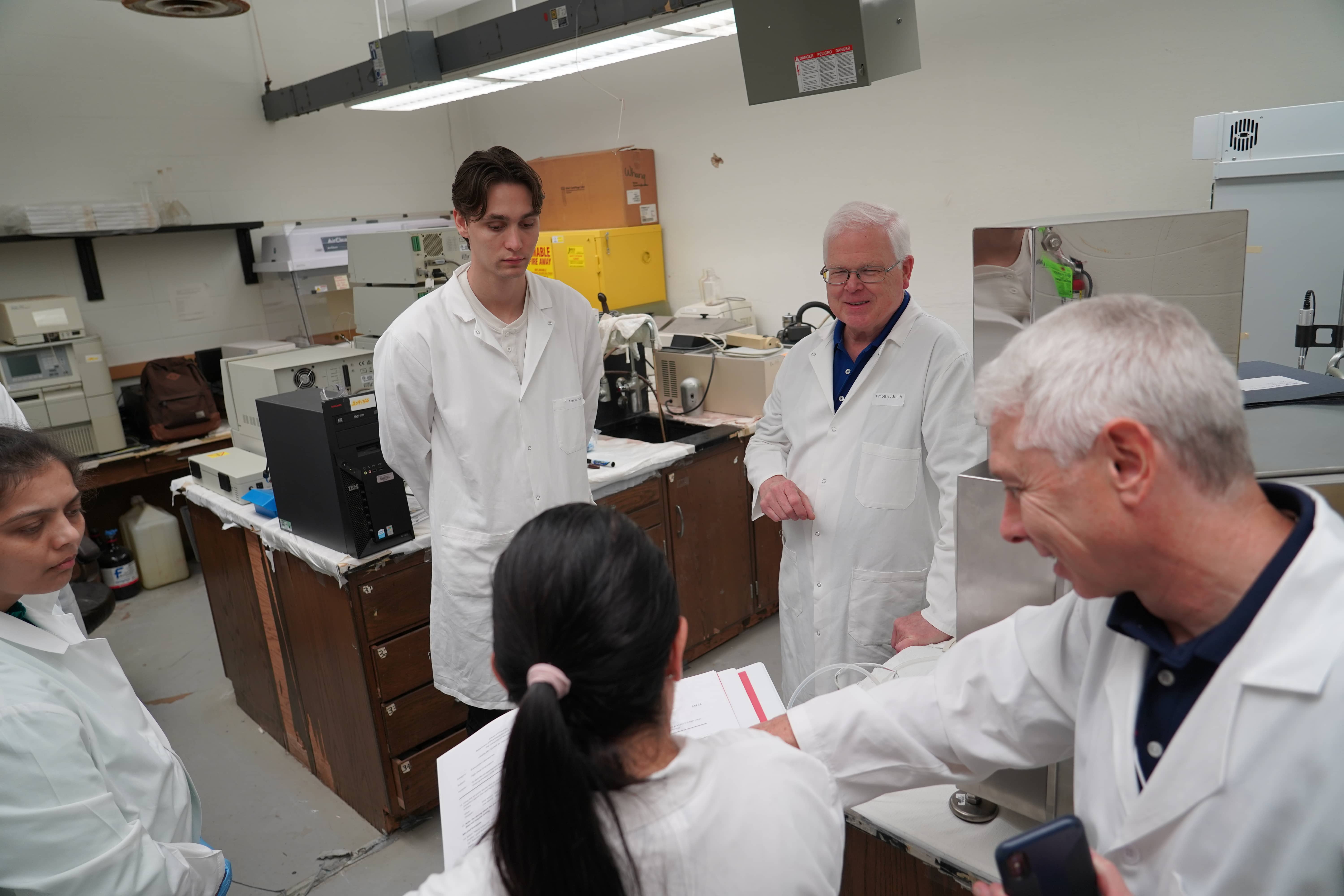

Experts from industry and academia present lectures and supervise laboratory assignments that provide an in-depth overview of the development, manufacturing, and quality control of solid oral dosage forms. Lectures explore the concepts involved in designing tablet formulations and manufacturing processes using QbD principles, from selecting excipients based on preformulation data to regulatory strategies for making post-approval changes to the formulation and/or manufacturing process for NDA/ANDA drug products.

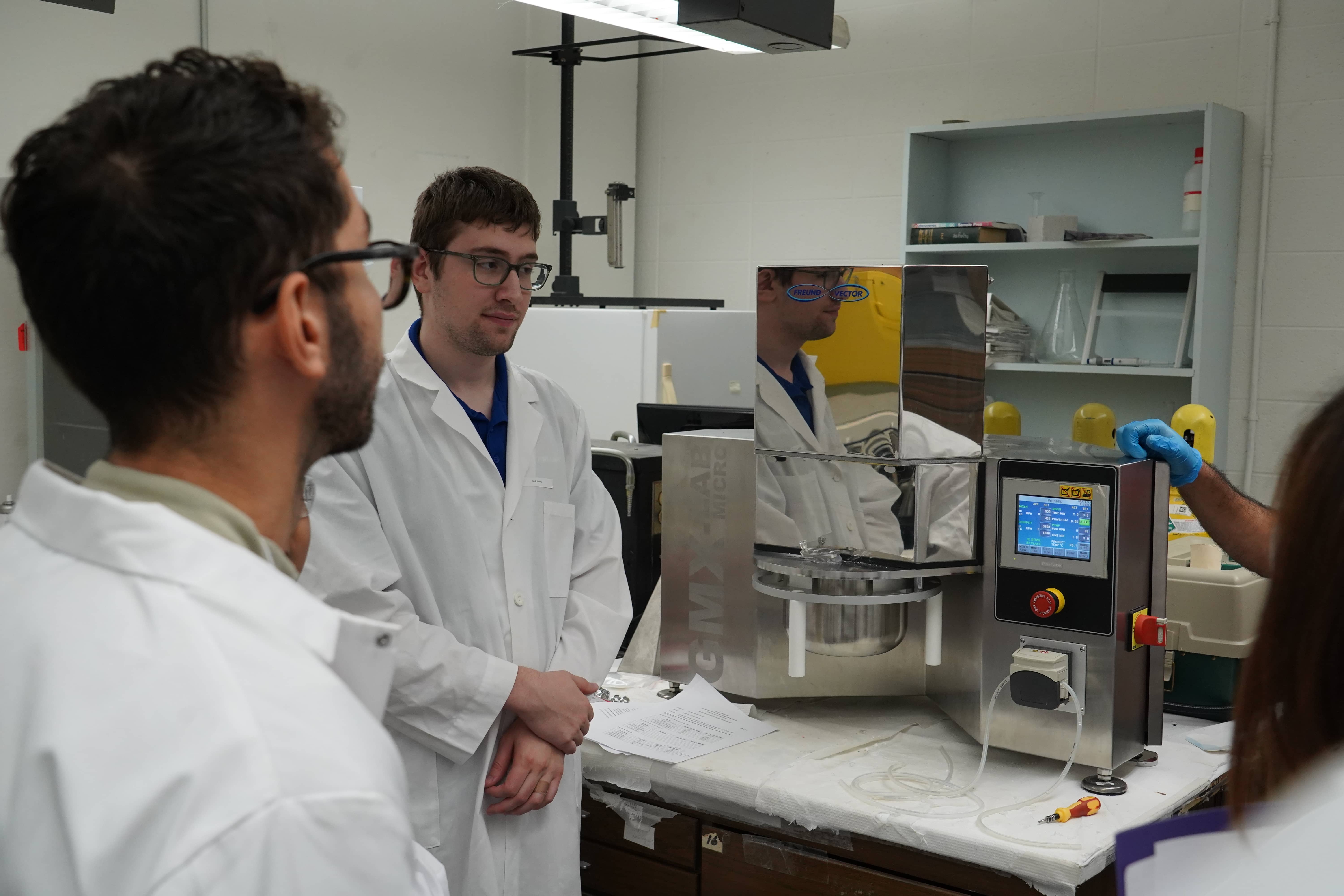

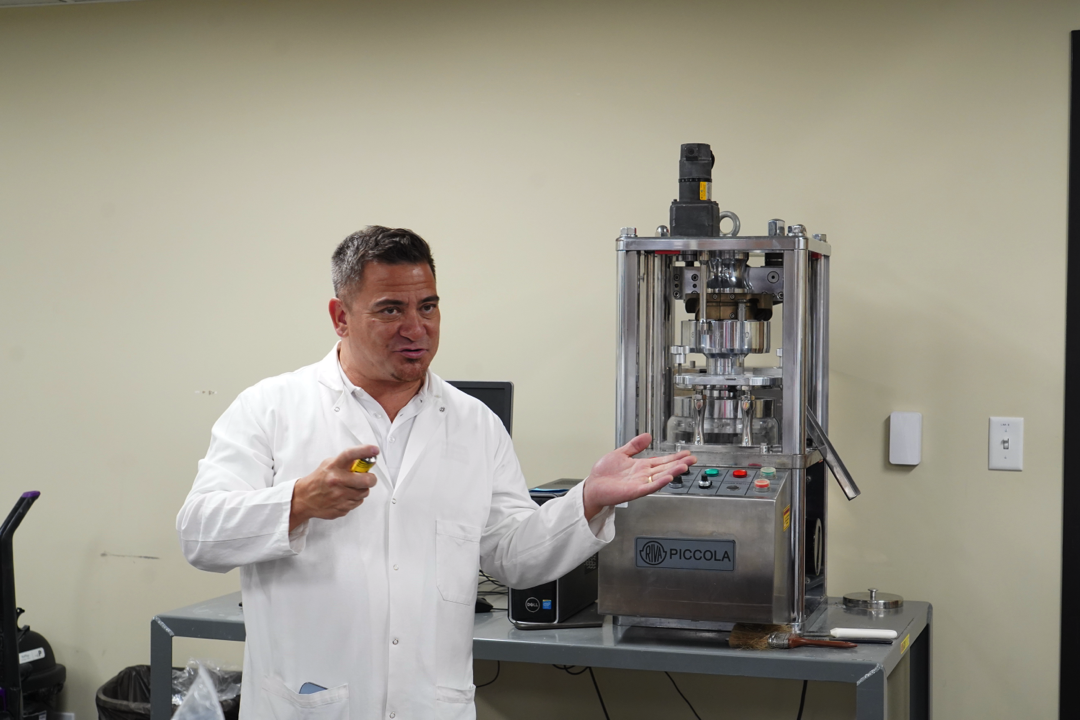

The laboratory portion of the course is designed to provide attendees with practical, hands-on experience in unit operations discussed in lecture sessions. Laboratory sessions include hands-on experience conducting pre-formulation studies, preparing powder blends and granulations (e.g., hot-melt extrusion and high shear granulation), manufacturing tablets (e.g., instrumented tablet press, 3D printing, and tablet coating operations), and conducting in-process and quality control release tests.

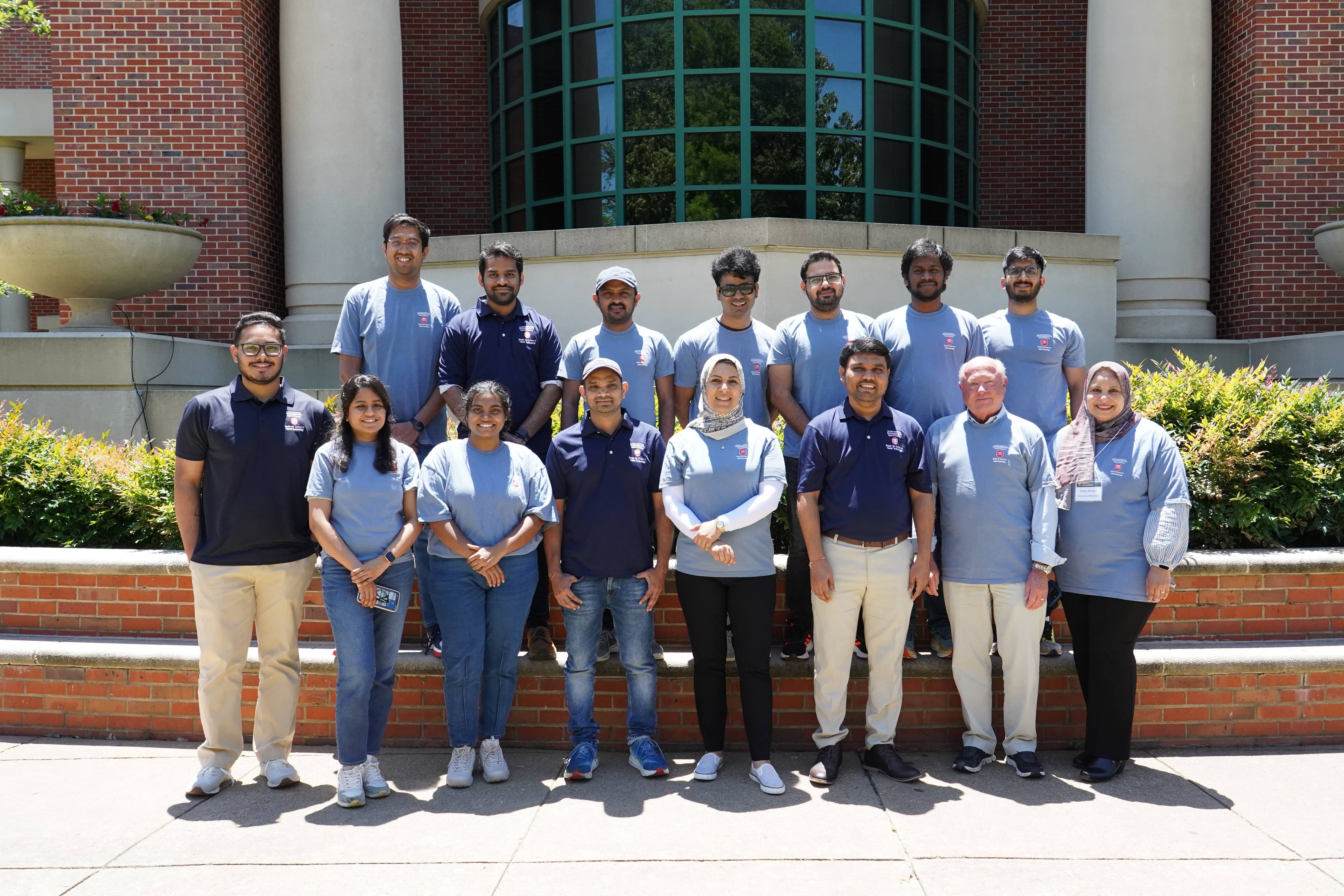

The course, initiated in 1998, has trained over 2,000 attendees, including scientists and engineers working in formulation development, process development, manufacturing, analytical method development, and quality control, and sales and marketing professionals from the pharmaceutical, dietary supplement, animal health, and food industries. Other attendees have been from excipient and equipment suppliers and regulatory authorities, including the FDA and Health Canada.

Monday

7:15 - 8:00 am

Registration - Continental Breakfast Provided; Thad Cochran Research Center Room 1000

8:00 am

Welcome, Introductions, and Orientation

Dr. Michael A. Repka, Program Director & Distinguished Professor, Department of Pharmaceutics and Drug Delivery, School of Pharmacy, University of Mississippi.

Dr. Sateesh Kumar Vemula, Program Director of Hands-on Course in Tablet Technology

9:00 am

Pharmaceutical Development: An Overview

Dr. Bill McLaughlin for Dr. Robert Marion - The University of Mississippi

10:00 am

Role of Engineered Excipients

Mr. Joao Marcos Assis - BASF Pharma Solutions

11:00 am

Mixing & Blending

Dr. Kerry Johanson - Material Flow Solutions

12:00 pm

Lunch & Learn Session (BASF)

1:00 - 5:00 pm

Laboratory Sessions

_____________________________________________________________________

Tuesday

7:15 - 8:00 am

Continental Breakfast

8:00 am

Pre-Formulations Studies

Dr. Walt Chambliss - The University of Mississippi

9:00 am

Granulation and Drying

Mr. Ed Godek - Glatt Air Techniques, Inc.

10:00 am

Powder Compaction and Compression

Mr. Bob Sedlock - Natoli Engineering Company, Inc.

11:00 am

Extrusion and Spheronization

Ms. Alva Godfrey - LCI Corporation

12:00 pm

Lunch & Learn Session (Lubrizol)

1:00 - 5:00 pm

Laboratory Sessions

_____________________________________________________________________

Wednesday

7:15 - 8:00 am

Continental Breakfast

8:00 am – 12:00 pm

Laboratory Sessions

12:00 pm

Lunch

1:00 - 5:00 pm

Laboratory Sessions

_____________________________________________________________________

Thursday

7:15 - 8:00 am

Continental Breakfast

8:00 am

Coating of Pharmaceutical Oral Dosage Forms

Mr. Kapish Karan - Global OSD leader, Ashland

9:00 am

Quality Control: Analytical Testing

Mr. Mike Buckley - Sotax

10:00 am

Hot Melt Extrusion

Dr. Michael A. Repka - The University of Mississippi

11:00 am

Scale-Up Considerations

Mr. Ed Godek - Glatt Air Techniques, Inc.

12:00 pm

Lunch

12:45 pm

Class Picture

1:00 - 5:00 pm

Laboratory Sessions

_____________________________________________________________________

Friday

7:15 - 8:00 am

Continental Breakfast

8:00 am

BA/BE, IVIVC, FDA/SUPAC Guidelines

Dr. Walt Chambliss - The University of Mississippi

9:00 am

Pre-Market Stability

Dr. Eman Ashour - The University of Mississippi

10:00 am

Compaction Simulation

Dr. James Stephens - KORSCH America Inc

11:30 am

Wrap-Up

LAB 1 – Preformulation

Evaluate properties of a pharmaceutical API, powders, and polymers utilizing:

- Particle surface area analysis

- Porosity analysis

- Particle size and shape analysis

- Density analysis

- Moisture adsorption/desorption isotherms

- Texture analysis

- Thermogravimetric analysis

- Differential scanning calorimetry

LAB 2 – Granulation and Extrusion/Spheronization

Processing of a pharmaceutical API and excipients to form granules and extrudates by:

- High shear mixing and wet granulation

- Low shear mixing and wet granulation

- Extrusion/Spheronization

- Fluid bed drying

LAB 3 – Tableting

Evaluate excipient/drug compressibility and compressibility of wet granulated vs. direct compression tablet formulations utilizing:

- Instrumented single punch tablet press

- Instrumented rotary tablet press

- Equipment to monitor weight, thickness, and breaking strength of tablet compacts

- Software to determine scalability from small to large-scale production presses

LAB 4 – Hot Melt Extrusion, 3D Printing and Tablet Evaluation

Evaluate processing of hot melt extruded forms using:

- Hot melt extruder

- 3D Printing

Perform tests to evaluate quality control attributes of tablets using:

- Tablet dissolution apparatus, real-time and interval drug release testing

- Tablet disintegration testing

- Tablet friability testing

LAB 5 – Fluid Bed Granulation/Particle Coating and Tablet Pan Coating

Evaluate granulation of an API/excipient blend and film coating of non-pareil particles using:

- Fluid bed granulator/Wurster particle coater

Pan coat tablets using:

- Side-vented tablet coating pan

| Tablet Course | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Ashland | Wilmington, DE |

| BASF Pharma Ingredients and Services | Tarrytown, NY |

| Colorcon | West Point, PA |

| Distek Inc. | North Brunswick, NJ |

| Dow Chemical U.S.A. | Midland, MI |

| Evonik, Inc. | Piscataway, NJ |

| Fitzpatrick Corporation | Elmhurst, IL |

| Foremost the USA | Baraboo, WI |

| Gattefossé USA | Paramus, NJ |

| Glatt Air Techniques, Inc. | Ramsey, NJ |

| Hanson Research Corporation | Chatsworth, CA |

Kerry Group | Wisconsin, USA |

| IFF Nutrition & Biosciences | New Century, KS |

| LCI Corporation | Charlotte, NC |

| Mallinckrodt Specialty Chemicals Corporation | Hightstown, NJ |

| Micromeritics | Norcross, GA |

| Moreflex, Inc. | Greensboro, NC |

| Natoli Engineering | St. Charles, MO |

| pION | Woburn, MA |

| Quest International | Hoffman Estates, IL |

| Roquette America | Keokuk, IA |

| Sartorius Corporation | Edgewood, NY |

| SMI, Specialty Measurements Inc. | Lebanon, NJ |

| Sotax | Hopkinton, MA |

| SPI Polyols, Inc. | Wilmington, DE |

| Surface Measurement Systems | Allentown, PA |

| Texture Technologies | Marietta, GA |

| Thermo Fisher Scientific | Waltham, MA |

| Freund-Vector Corporation | Marion, IA |

Travel

The cost of one round-trip shuttle is $145 per person, and the cost of a one-way shuttle is $95 per person. To book a round-trip shuttle, flight information for both travel dates is required at the time of booking. Payment is required prior to your first shuttle with either a VISA or MasterCard.

Shuttle requests should be made at least (6) business days before the date of travel to ensure a shuttle is available. Use the Memphis Airport Shuttle Request Form to make your transportation request. Further information can be found at the Ole Miss Outreach website. For questions, please email shuttle@olemiss.edu or call the office at 662-915-5132.

Shuttles will be confirmed via e-mail. Please meet your shuttle driver inside the airport and nearby Baggage Claim, Area B escalator.

Lodging

*For discounted room rates, please click the links below.*

The Inn at Ole Miss

Courtyard Marriott Oxford

Participants are responsible for making their own room reservations. The Inn at Ole Miss and Courtyard Marriott in Oxford have reserved block rooms for Tablet Course participants. The Inn at Ole Miss is on campus, close to on-campus lecture and laboratory facilities. The Marriott is located adjacent to the University of Mississippi campus at 305 Jackson Avenue East, and is also close to campus facilities.

Reservations at either of the referenced hotels should be confirmed 2-3 weeks before the course to receive the reduced rates.

Area

The city of Oxford, Mississippi, offers something for all music, food, literary, and art interests. Learn more at the Visit Oxford website.

Highlights from Past Conferences

Expand image:

Expand image:  Expand image:

Expand image:  Expand image:

Expand image:  Expand image:

Expand image:  Expand image:

Expand image:  Expand image:

Expand image:  Expand image:

Expand image:  Expand image:

Expand image:  Expand image:

Expand image:  Expand image:

Expand image:  Expand image:

Expand image:  Expand image:

Expand image:  Expand image:

Expand image:  Expand image:

Expand image:  Expand image:

Expand image:  Expand image:

Expand image:  Expand image:

Expand image:  Expand image:

Expand image:  Expand image:

Expand image:  Expand image:

Expand image:  Expand image:

Expand image:  Expand image:

Expand image:  Expand image:

Expand image:  Expand image:

Expand image: